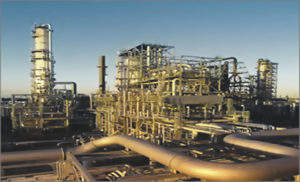

Mee Industries Inlet Air Fogging Systems for Oil, Gas and Petrochemical Processing

Mee Industries is the world leader in gas turbine inlet air fogging for power augmentation. The company has been making fog systems for gas turbine applications since the early 1990s and has successfully completed more than 800 installations.

Mee Industries offers efficient and cost-effective solutions for all types and sizes of gas turbines. We will work with you every step of the way to ensure your project is a complete success.

Fog-based evaporative cooling

At a cryogenic facility, fog-based evaporative cooling has been effective in gathering 18% more gas during the hot summer days. This gas is then processed and routed to the gas pipeline system to be shipped to downstream receiving facilities.

Increasing gas volumes from wells

Compressors that are working at their max-load ISO rating may have difficulty keeping up with processing demands on hot summer days. In one instance, a facility containing three refrigeration / de-ethanizer compressors with a capacity of over 500MMcf/d with natural gas liquid production of 50,000Bbls/d saw days when less than 400MMcf/d would come during the summer.

Inlet air fogging for summer cooling

When it comes to gas turbine inlet air fogging solutions, one company stands above the rest. With over 80% of the installed capacity of inlet fogging systems, Mee Industries is the inlet fogging industry leader.

The MeeFog system has the following benefits:

- Increases output by up to 20% or more

- Improves heat rate by up to 5%

- Reduces NOx emissions by up to 30%

- Up to 100% evaporation efficiency

- Easy retrofit and fast installation

- Fog inter-cooling gives additional boost

- Reduces fuel consumption

Gas turbine air fogging return on investment

One company augmented the power of two of its GE Frame 5 CTs, which translated into savings in the range of $10,000-plus per day, assuming a daily average increase in pumped gas at 9% (9% in a 400MMcfd comes to 36MMcfd). At a rate of $300 per MMcfd, this increases revenue at the plant by $10,800 per day.

In comparison, the cost of operation of the fog system works out at $603 per day for 24 hours of continuous operation: 720gal of RO water at $0.05/gal equals $360/day; power to fog skid per day = $75/day; maintenance cost estimate of $2/hr = $48/day; amortization of capital at $3/hr = $72/day.

Proven gas turbine inlet air fogging technology

A system of high-pressure pumps pressurizes demineralized water, which flows through a network of stainless-steel tubes to the MeeFog nozzles located in the gas turbine inlet duct. Each proprietary MeeFog nozzle atomizes the water into trillions of ultra-fine fog droplets per second.

Due to its large evaporative surface area and the small droplet size, the fog evaporates, cooling the inlet air and providing a cost-effective power boost. The self-contained MeeFog skid comes complete with a programmable logic controller (PLC) control system.

Advanced high-pressure fogging nozzle design

Mee Industries manufactures the world’s best impaction-pin type fog nozzle. Droplet size is the single most important factor governing fog system performance. Smaller droplets mean faster and more efficient cooling, less wetting of duct surfaces and greatly reduced compressor blade distress. The MeeFog nozzle sets the standard for inlet fogging nozzles and has been shown to consistently out-perform other nozzles.

Products and Services

Video

White Papers

Press Release

Mee Industries has introduced a new high-pressure filter which simplifies nozzle maintenance. Pump seals degrade over time causing small particles of seal material to enter into the high-pressure feedlines which can plug fog nozzle filters. The high-pressure filter captures particles and reduces

Read moreMee Industries has announced that its seal-flushed pumps provide extended seal life for fog pumps. These flushed pumps are designed for intense, continuous-duty gas turbine DI water-fogging application and offer a near maintenance-free operation, energy-efficiency and long life. Foggin

Read moreMee Industries is providing turnkey fog systems for cooling inlet air, in order to boost the gas turbine power output. The new water treatment and storage option can be added to provide a fully engineered single sourcing of components. Benefits of turnkey installations<

Read moreRegional Offices

16021 Adelante St

California 91702

Irwindale

Other

United States of America