fma systems Terminal Automation Solutions, Loading Gantry Skids and Associated Service Offerings

fma systems provide terminal automation solutions and products to the petrochemical industry. Over the years fma systems have grown from just being a computer systems integrator to now providing a full range of services, from front-end engineering design, equipment supply, installation of hardware products such as tank level gauges and loading gantry skids, commissioning and training, on-going support and maintenance.

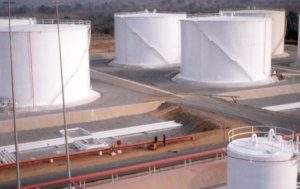

After 25 years in the petroleum industry, fma systems fully understands the needs of its customers – both large and small – and offers a comprehensive range of solutions for a range of terminals from 3 loading positions to large terminals with over 1,000 loads per day. Our terminal automation system provides personnel and product access control and security; movement and storage of products including road and industrial bitumen, ethanol blending together with various other chemicals and petroleum products. Comprehensive stock control allows deliveries to be balanced against receipts and tank holdings and provides product reconciliation reports and ERP interfaces.

We have established a repertoire of proven automation to fulfill virtually all requirements of today’s terminal and depot distribution. We are based in Chalgrove, near Oxford, in the UK. However, our customer base spans many countries worldwide.

Terminal Automation software for the petrochemical industry

Regulatory and economic requirements for the business control of receipt, storage and delivery of products are more challenging today than they have ever been. These continual changes require comprehensive, open, flexible and cost-effective management systems. fma has succeeded and thrived in a volatile industry by pioneering leading-edge software solutions and forging strong strategic alliances and technical partnerships.

fma systems’ proprietary products taOpen and DepotVisor are immensely flexible and innovative computing products, designed to be run on either a single workstation or on distributed systems.

Local or Remote Terminal Automation

Our software enables many of the users, either locally or remotely, to simultaneously monitor and control depot operations, as it is designed to work with the internet. A 3D graphic of the site enables the operator to see and control the status of pumps, valves and other items of plant equipment.

taOpen and DepotVisor are capable of interfacing with major supply chain management systems such as SAP™, J D Edwards™ and Sun Systems™. This allows load requests to be entered at head office or other locations and then sent to other locations for loading. On completion of loading our software sends back reporting information to the supply chain management system.

Depending on customer requirements, taOpen and DepotVisor can be configured to provide any or all of these functions locally and remotely:

- Vehicle and pedestrian access controls

- Supervision of vehicle loading and unloading

- Stock management

- Tank level and temperature gauging

- Tank farm control and monitoring

- Additive and blending control

- Vehicle bunkering

- Order processing and invoicing

- Management reporting

- Internet-ready communications to other supervisory systems

- Two and three-dimensional graphics

Our largest site currently using the system has some 1,000 vehicle movements a day, while the smallest has just 20.

Terminal and Depot Instrumentation

fma specialise in the system design and product specification of field instrumentation. By not being limited to any particular suppliers they can offer the right product at the right price.

Instrumentation available includes:

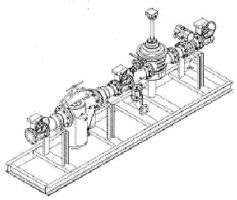

- Top and bottom loading skids

- Bioethanol and denaturant blending skids

- Coriolis, turbine and positive displacement meters

- Analogue blending and injection

- Vehicle earthing and overspill monitors

- Loading and vapour arms and hoses

- Electronic preset and flow controllers

- Radar and magnetostrictive tank level gauging

- Tank level safety monitoring

Integrated Terminal Automation Packages

Typical of work currently being undertaken by fma systems is a total package solution integrating terminal automation, loading gantry skids and tank farm monitoring. A customer in the Delta region of Nigeria is currently under construction with 20 storage tanks and six top-loading gantries. This solution was satisfactorily inspected by the customer’s representative and certified for shipment to Nigeria; we wait scheduling of installation by a local contractor prior to the commissioning and training of site personnel by our engineering services department.

Products and Services

Video

White Papers

Related Projects

Tornio Manga LNG Terminal

West Ells SAGD Project, Alberta, Canada

Vladivostok LNG Project, Primorye Territory

Press Release

One of Fma Systems' most recent innovation allows the Isoil Impianti SpA Vega II electronic head to be used as the loading controller. The system is designed to be used in an unmanned operation, allowing loading to take place 24 hours a day without additional operational staff. Fma's

Read moreRegional Offices

37 Monument Business Park

Chalgrove

Oxfordshire

OX44 7RW

Other

United Kingdom