Rysco Corrosion Services Inc Internal Corrosion Monitoring using Weight-Loss Corrosion Coupons and Electronic Probes

Rysco Corrosion Services Inc is an oilfield services company dedicated to providing internal corrosion monitoring solutions to oil and gas producers.

Rysco services include:

- Monitoring equipment supply and specification

- Threaded and hydraulic access-fitting field service

- Electrical resistance (ER), linear polarisation resistance (LPR) and galvanic electronic monitoring

- Weight-loss corrosion coupon analysis

- Sessile/ planktonic bacterial sampling and reporting

- Field sampling water for iron/manganese and chlorine residuals

- Pipeline external coating inspections

Rysco also provides audit services related to internal corrosion monitoring and speciality chemical usage. Proper monitoring should ensure that all mitigation strategies have the potential to be evaluated. Rysco employs educational resources that enable the use of sophisticated analytical equipment to monitor corrosion and speciality chemicals.

Internal corrosion monitoring equipment

Along with the determination of monitoring locations, equipment selection and specification is one of the most important elements of internal corrosion monitoring. Rysco supplies hydraulic and standard access fittings as well as electronic probes for internal corrosion monitoring. Once a monitoring location has been determined, it is equally important to position the weight-loss corrosion coupon or probe within the most representative area of the pipeline.

Field service of access fittings, corrosion coupons and probes

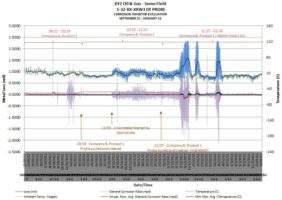

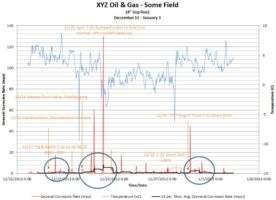

Weight-loss corrosion coupons (mechanical) and probes (electronic) are complementary methods for monitoring internal corrosion. Rysco supplies, installs, and services the most common commercial products available, including coupons and ER, LPR and galvanic probes. The primary advantage to electronic monitoring is the ability to monitor corrosion events in hourly intervals close to real time. This compares with the time-weighted averages provided by weight-loss corrosion coupons.

Bacterial sampling using sessile and planktonic SRB/ APB

Bacteria can be a cause of corrosion during oil and gas production. It is commonly referred to as microbial-influenced corrosion. The accepted standard for bacterial testing in oilfield produced water is serial inoculation via dilution. Rysco can sample, inoculate and report on the most common types of oilfield bacteria using this method, including planktonic (free floating) and sessile (attached) sulphate-reducing bacteria (SRB), as well as acid-producing bacteria (APB).

Additional bacterial testing may be completed by using BARTTM tests to identify SRB, APB, iron-related bacteria, slime-forming bacteria, heterotrophic aerobic bacteria, denitrifying bacteria, and nitrifying bacteria.

Techniques used meet NACE TM0194 ‘Field Monitoring of Bacterial Growth in Oil and Gas Systems’ standards.

Field sampling of produced water chemistries

Produced water chemistries are a valuable tool in monitoring internal corrosion on pipelines. Full water analysis, iron/ manganese concentrations and corrosion-inhibitor residuals can provide an indication of the corrosiveness of oilfield-produced water. The readings can also indicate the effectiveness of corrosion inhibitors or corrosion mitigation programmes.

The representative sampling of waters using proper technique is equally as important as lab analysis on the supplied produced water sample. Rysco meets API RP 045 ‘Recommended Practice for Analysis of Oilfield Waters’ standards when collecting produced water samples.

External coating inspections of pipelines

Rysco conducts indirect external coating inspections on buried pipelines in order to measure and assess the protective coating on the outside of the pipeline and pinpoint any coating anomalies that may be indicative of exposed metal. The equipment and procedures used are in full compliance and support of the methods approved by ANSI/NACE SP0502-2010 ‘Standard Practice for Pipeline External Corrosion Direct Assessment Methodology’.

Rysco uses several complementary methods to evaluate the external coating in order to stamp out the weaknesses of the individual methods, providing confidence in the measured anomalies. The indirect inspection methods used by Rysco Corrosion Services comprise:

- Alternating current coating attenuation (ACCA)

- Alternating current voltage gradient (ACVG).

- Depth of cover

- Land use

- Right of way inventory

- Close interval potential surveys

Internal corrosion monitoring and speciality chemical audit services

Rysco provides audit services for the evaluation and presentation of recommendations related to existing and proposed internal corrosion monitoring programmes. These can be complemented with audits for the evaluation and presentation of recommendations relating to existing and proposed production speciality chemical programmes.

Please use the contact details below to send us your business enquiry.

Products and Services

Video

White Papers

Related Projects

Merrick Mainline Pipeline Project, British Columbia

River Humber Gas Pipeline Replacement Project, North Lincolnshire

Tubridgi Gas Storage Project

Northeast British Columbia (NEBC) Expansion Project, British Columbia

Trans Mountain Expansion Project

Press Release

Regional Offices

3 – 5647 Wolf Creek Dr

Lacombe, AB

T4L 2H8

Canada