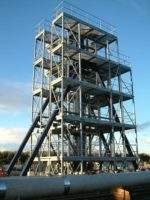

GL Flow Centre Flow Meter Calibration, Instrument Calibration, Valve Testing, Erosion Testing, Flow Testing and Development

The GL Flow Centre provides testing, calibration and qualification services to customers in the oil and gas, offshore and pipeline industries.

The former Bishop Auckland test facility has gained an international reputation for technical expertise, quality of service and in-depth knowledge of all aspects of the flow measurement and control industry. Their range of services include:

Flow meter calibration

With a particular emphasis on calibrating at or near the operating pressure and with the actual working fluid, the GL Flow Centre can undertake natural gas flow meter calibrations throughout the year on whole metering packages.

Ultrasonic, turbine and venturi flow meters are calibrated to satisfy the customer’s need to reduce the uncertainty in flow measurement. This service is undertaken for the oil and gas, offshore and pipeline industries

The UKAS accredited calibrations cover flow meters from 2in (50mm) to 24in (600mm), although larger flow meters can also be accommodated. In undertaking the work the GL Flow Centre ensures industry standards are complied with.

Instrument calibration

The UKAS accredited instrumentation laboratory primarily calibrates temperature, pressure and differential pressure instrumentation.

Recent improvements now allow GL Flow Centre to specialise in gas dead weight testers, absolute pressure, negative gauge pressure and resistance.

Pressures of up to 400bar can be accommodated and the GFC provides some of the lowest uncertainty measurements in the world.

Valve testing

The GL Flow Centre sub surface slam shut safety valve (SSSV) test facility is used by many operators and manufacturers. They use the facility to assess the performance of a wide range of these safety critical devices.

The facility can test valves under realistic conditions and can achieve flow velocities of over 120m/s.

Erosion testing

The GL Flow Centre erosion testing facility is used for undertaking tests on components and equipment over a range of controlled operating conditions.

The flow through facility utilises sand injection into the high-pressure gas. This ensures a much more accurate assessment of erosion compared to using re-circulation systems.

Sand can be injected into the gas flow at rates of up to 100kg/hr enabling accelerated testing to be undertaken. The facility has undertaken a wide range of qualification testing on valves for many offshore and onshore operators and manufacturers.

Flow testing

The large facility enables a wide range of other flow testing to be undertaken. These include inspection pig blow over testing and, valve leakage assessments. This process can be used to ascertain pressure drop measurements in pipelines.

Accurate assessment of the pressure drop in pipelines can save operators money by optimising pipe diameters and compressor requirements. Experimental work at the GL Flow Centre has led to substantial cost savings for a number of offshore operators.

Development

The GL Flow Centre also works with meter manufacturers to undertake development and type approval testing. The large facility and the ensured confidentiality of the work are an attractive proposition for manufacturers.

As an ISO 17025 UKAS accredited calibration facility (Lab: 0555) the GL Flow Centre ensures the trace ability and quality of its measurements.

The GL Flow Centre

The strategic position of the GL Flow Centre provides a wide range of pressures (up to 60bar) and flow rates (up to 30mscmd) throughout the year. Extensive pipe work arrangements can be accommodated in the 90m-long test area. Full size components such as meters, regulators, valves and filters can be calibrated and tested under realistic operating conditions.

Of increasing importance to operators is the ability of the GL Flow Centre to undertake qualification testing of components such as valves, using realistic operating conditions.

Modelling and small scale testing can play their part but experience has shown that ultimately full scale testing provides the greatest confidence.

In addition to flow calibration, the GL Flow Centre also offers UKAS accredited calibration of pressure and temperature instruments.

Products and Services

Video

White Papers

Related Projects

Press Release

GL Noble Denton has published a new guideline for the certification of blow-out preventers (BOPs). The guideline clearly defines the process to be undertaken by independent third-party certification bodies in certifying the integrity of the asset, which monitors and controls the flow of oil and g

Read moreGL Noble Denton will be exhibiting its portfolio of services and solutions at OTC 2011, the world's foremost event for the development of offshore resources in the fields of drilling, exploration, production, and environmental protection on booth number #2541.

Read moreGL Noble Denton, the global independent technical advisor to the oil and gas industry, has partnered with control system software testing specialist Marine Cybernetics to improve performance, reliability and planning for all types of offshore vessels. The partnership will see GL Noble De

Read moreGL Noble Denton, the global independent technical advisor to the oil and gas industry, has signed an agreement with TAQA Energy BV, a subsidiary of Abu Dhabi National Energy Company PJSC (TAQA), to provide a business-critical gas management system for the commercial operations of its Bergermeer G

Read moreFollowing a year of slow economic recovery, unstable price fluctuations and damaging incidents in the Gulf of Mexico and China, the oil and gas industry is predicting a healthy investment in new exploration and market opportunities over the next 12 months, a new report on the future of the sector

Read moreGL Noble Denton has signed a Master Service Agreement with Aramco Overseas Company for vendor inspection services. GL Noble Denton will inspect the manufacturing process of all types of oil and gas equipment at the vendor's site. The contract has a validity of three years and covers services to b

Read moreGL Noble Denton was awarded the Gas Industry Safety Award for Safety Related Research 2010 by the Gas Industry Safety Group (GISG) as part of their 'Decade of Excellence Awards'. The award recognises safety research programmes, which have contributed to a continual improvement in gas safety in t

Read moreOffshore service vessels (OSV) are becoming larger, more specialised and technically sophisticated as a result of the rising demand for more complex deepwater field developments, including the Gulf of Mexico. Currently, there are some 2,500 OSV worldwide, with a steady growth projected from now u

Read moreGermanischer Lloyd (GL) will be attending Offshore Europe 2009, which will be held between 8-11 September 2009, in Aberdeen, UK. Visit the company at stand 607. Now with the newest members of the GL Group, Noble Denton, the premier provider of life-cycle marine and offshore engineering

Read moreLoughborough, UK – International engineering consultancy Advantica is pleased to announce that Paul Shrieve has been appointed as Executive Director, UK and Europe, with effect from 3rd January 2007. Paul’s role will include business development, sales and project delivery. He will be based at bo

Read moreRegional Offices

Holywell Park

Ashby Road

Leicestershire

Loughborough

LE11 3GR

Other

United Kingdom