SATE Research, Engineering, Dynamic Simulation and Diagnostics

Systems and Advanced Technologies Engineering (SATE) is a research and engineering company supporting customers’ innovation processes and projects.

Our core activities are consultancy and simulation services, based on proprietary computer modelling software, and the development of custom-made software products, either for engineering, testing or real-time onboard/infield operation.

We specialise in the dynamic simulation of power plants, oil and gas processing plants, turbines, compressors, pumps, vehicles and special machines, in signal processing and data analysis and in the design and analysis of CAN protocol (CANbus) data networks.

Our expertise particularly covers fluid handling machines, gas and liquid thermodynamics and processing, phase separation, pressure pulsation analyses according to API 618 and API 674 standards, vehicle system dynamics and controls.

In providing the above services and products we follow procedures based on a certified quality system complying with ISO 9001-2008 standards.

Rotating machine-process simulation

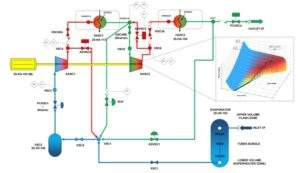

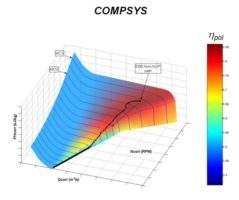

Our modelling suite COMPSYS™ enables the highly accurate study of dynamic interaction between centrifugal and axial flow compressors with drivers, process plant and controllers. Advanced process thermodynamics, dynamic machine performance mapping, valve and pipeline flow dynamics under compressible regime, gas or steam turbine drivers, constant speed or VSDS electric motor drivers and power supply network dynamics are typical physical phenomena studied by this high-performance suite.

We analyse steady state conditions and typical transients, such as normal and emergency shut downs (ESD), machine start-up sequences (series and parallel), process changes, valves or other equipment failure events.

The main outcomes of the studies, under normal and off-design dynamic conditions, are: verification of the proper routing and sizing of control lines and valves; verification for the need and sizing of hot by-pass (recirculation) valves; verification of process and heat exchanger performance under single or phase change conditions; analysis of controller stability and remedial to possible instabilities, particularly non-linear, preliminary tuning of the antisurge, performance and load sharing controls prior to commissioning; definition and verification of operational procedures for in-field testing; and machine map verification with real fluid operation.

Pressure pulsation analyses and flow induced vibrations (FIVs)

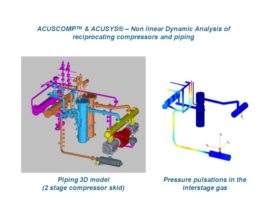

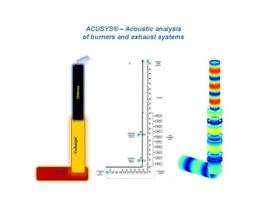

Our software programmes ACUSCOMP™ and ACUSYS® allow the study of reciprocating machine installations against acoustic pulsations and flow-induced vibrations, according to approach 3 of API 618, approach 2 of API 674 standards and RP 688 guidelines. They simulate, sequentially in the time and in the frequency domains, the compressor thermodynamic cycle and the dynamic response of the processed fluid in the plant.

The models consider the mutual non-linear interactions between machines and plant; i.e. whole piping acoustic wave propagation and pressure response, in-cylinder thermodynamics and dynamic intake/discharge flow, compressor valve dynamics, including load step commands, variable speed drivers, leakages through piston and rod seals (if needed for model-based diagnostics or troubleshooting analysis), critical speeds of variable speed compressors for each piping part (suction, interstage and discharge) and 3D shaking forces at piping bends and junctions.

With these tools SATE provides engineering analyses of pulsation dampeners, piping, heat exchangers and other equipment interfaced with the rotating machines and turbulence-induced phenomena, such as ‘riser singing’, T-joint, obstructions and valves activated by acoustic resonances.

Diagnostic solutions

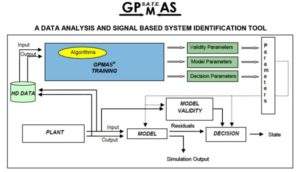

We develop innovative diagnostic algorithms, methods and software based on models of various transparent or black box type, e.g. neural networks, or on unsupervised data mining methods, e.g. based on feature and patterns extraction, clustering and correlation analyses for self learning novelty and fault detection.

Our process or machine virtual sensors and diagnostic software can be embedded in custom and commercial electronic hardware for real-time diagnostics, networked in several ways with the plant, e.g. CAN bus or other field bus technologies. Our solutions have been already embedded in the electronics of cars, trucks, buses, industrial and naval engines and are being studied for spacecraft telemetry analysis.

Due to their generality these methods can be applied also to infield or telemetry data from oil and gas processes and machines, with the purpose of extracting relevant knowledge about the system behaviour, to detect subprocesses or components with unexpected or novel behaviours to be further analysed, with a given priority, and to identify possible unknown relationships among the system signals and parameters.

CAN networks

Working with vehicle systems has given us particular expertise in managing data networks based on the CAN protocol and associated hardware, so we can support our customers in designing or upgrading CANbus systems for any application, completing the desktop-to-field path.

International service

We serve several renowned international and national customers based in the Mediterranean, central and northern Europe and in Asia, including oil companies, leading OEMs, and EPCs both in the upstream and downstream industry sectors. SATE is qualified for the oil and gas sector through the Achilles JQS system.

SATE has provided essential steps in the development and engineering of several large oil and gas and pipeline projects in Western and East Europe, Asia and Africa.

European research and development project partnerships

SATE has been participating in qualifying European research and technology development projects (e.g. DIAMOND, MAGIC, METABO), growing fruitful partnerships with industries, research centres and academic institutions. For more than 20 years we have been a partner and member of the ‘Connections’ programme of Mathworks, producer of the renowned MATLAB® and SIMULINK® numerical simulation environments, by which we realise most of our solutions.

Products and Services

ACUSCOMP™ and ACUSYS® for Variable Speed Compressors

ACUSCOMP™ and ACUSYS® are a powerful pair of proprietary tools, whose capabilities are particularly evident for the analysis of variable speed gas compressors, and are even more useful in the industry to cope with variable load while guaranteeing high overall efficiency.

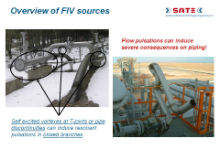

ACUSYS® for Flow-Induced Vibration Problems

SATE's ACUSYS® programme allows the company to provide consultancy to solve flow-induced vibration (FIV) problems deriving from internal fluid-dynamic/acoustic interactions caused by varieties of sources (Figure 1) that are inevitably present in plants.

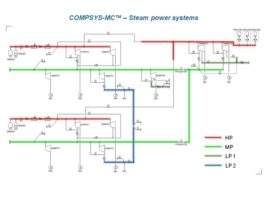

COMPSYS-MC™ – Dynamic Simulation of Steam of Single Compound Systems and Machines

SATE'S modelling suite COMPSYS-MC™ allows simulating thermodynamic processes and machines operated with a single component fluid, such as steam or pure propane processes.

COMPSYS™ Dynamic Simulation of Thermodynamic Systems and Machines

Our modelling suites COMPSYS™, COMPSYS-MC™ and TGSIM™ cover a wide range of interests to process, rotating machines and control engineers needing to verify the dynamic behaviour of their complex systems and possible off design conditions.

Processes and Machine Diagnostics

We develop innovative diagnostic algorithms, methods and software based on models of various types, transparent or black box type, e.g. neural networks, or on unsupervised data mining methods, e.g. based on feature and patterns extraction, clustering and correlation analyses for self learning novelty and fault detection.

Video

Press Release

SATE has just participated as invited speaker to the 2016 conference on big data from space - BiDS'16.

Read moreRegional Offices

Santa Croce 664/a

Venice, 30135

Italy