NRG Heat Exchangers Shell and Tube Heat Exchangers and Air-Cooled Coolers

Since 1995, NRG Heat Exchangers has been designing and manufacturing high-quality shell and tube heat exchangers and air-cooled coolers for the international oil and gas, (petro) chemical and power generation industries. In 2010 we joined forces with Frames to strengthen our international position and potential.

Shell and tube heat exchanger and cooler design and optimisation

Our highly trained and experienced engineers and welders have access to the latest software packages, state-of-the-art workshop and a large knowledge / experience database.

Together with an ambitious attitude and a motivating work environment, we ensure optimal thermal and mechanical designs for any project. Combined with a flexible organisation and a worldwide sales and distribution network, NRG has all the means to deliver market-leading products to internationally operating customers.

As part of Frames, NRG is now able to execute larger projects and participate in total system design and optimisation. We are only content with maximum results for our customers, proven by our full thermal and mechanical guarantee that we deliver on all supplied equipment.

Shell and tube heat exchangers

When a fluid stream requires cooling, condensing, heating or evaporation, shell and tube heat exchangers are used. Compared to other types of heat exchangers, the shell and tube have practically no limitations in operating pressure and temperature. They also excel in availability, reliability, durability and easy maintenance. NRG is specialised in engineering and manufacturing all available TEMA types, either vertical or horizontal.

We offer mechanical solutions for fouling applications and occasionally apply tube inserts to improve tube-side heat transfer and reduce tube-side fouling. Our engineers calculate exact sizing and advise our clients during the selection of materials to guarantee optimal efficiency and lifespan.

Air-cooled coolers

These heat exchangers offer fast and efficient fluid-to-air cooling / condensing in process systems where no or insufficient cooling fluid is available. They are also favoured because of their economical and operational advantages as they are less reliant on complex fluid cooling and conditioning systems.

In our quest for maximising market potential, we offer forced or induced draft coolers, including several options such as low noise fans, louvers (automatic / manual operated), heaters (electrical / conventional), variable speed drive systems, vibration switches and accelerometers, cabling provisions and hot air recirculation cabinets.

Steel and alloy heat exchangers and air-cooled coolers

The technologically advanced petrochemical and power generation industries demand the use of numerous steels and alloys. NRG is familiar with the majority of materials. Our shop engineers, metalworkers and welders are specialised in using the following materials:

- Carbon steel

- Stainless steel (SS304, SS316 and Duplex)

- Inconel 625

- 254 SMo

- Titanium Gr.2

- Non-ferrous: CuNi, admiralty and naval brass

Heat exchanger and cooler design

Our engineers start with the thermal rating and basic mechanical design executed during the sales stage. In close cooperation with the client, the design for each item is optimised with respect to plot-space limitations, noise reduction, power consumption, transportation, maintainability and investment. For the thermal rating and vibration analysis, both HTRI® and Aspentech HTFS® are used.

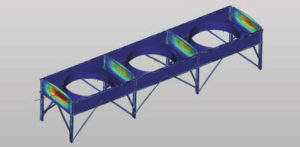

During the detailed engineering phase, the basic design will be developed to a full package of calculations, drawings and documents in line with client specification. Pressure vessel calculations are done by using the PV Elite™ software package, and the latest version of AutoCAD® is used for the complete product design engineering. To predict and analyse vibrations, displacements and stresses in the final product, our engineers can apply highly advanced finite element analysis methods.

To predict and analyse flow distribution in our products, our engineers use advanced computational fluid dynamics software.

Heating and cooling equipment according to specifications

NRG has supplied to the majority of the international OPCOs in the oil and gas, (petro) chemical and power generation industry. We design and manufacture our products according to a number of codes, standards and client specifications, including ASME VIII Division 1 and 2, NEN-EN 13445, PD5500, AD 2000-Merkblätter, Shell DEPS, BP specifications, and more.

Welding expertise for heat exchanger and cooling equipment

Working with multiple materials demands highly skilled, trained and qualified welders, a great insight into welding technology, plus state-of-the-art welding machines. The following processes have been mastered by our engineers and welders:

- Shielded metal arc welding (SMAW)

- Gas tungsten arc welding (GTAW)

- Flux cored arc welding (FCAW)

- Gas shielded metal arc welding (GMAW)

- Submerged arc welding (SAW)

- Electro-slag welding (ESW)

Since welding is a major part of our core business, preparation of the welding documents and, when necessary, (re) qualifying is executed in house.

Heat exchanger installation and maintenance packages

A dedicated service department is available for installment and/or supervision of the heat exchanger packages on-site. Our highly skilled and trained engineers can also extend the operational life and optimise efficiency of NRG systems via regular maintenance and modification implementation.

Products and Services

Video

Related Projects

Stublach Gas Storage Project, Cheshire

Iran-Pakistan Pipeline

Trans-Ecuadorian Oil Pipeline System (SOTE)

Press Release

NRG Heat Exchangers has released a white paper, available for download on Offshore Technology.

Read moreRegional Offices

De Hagen 19

8325 DB Vollenhove

Other

Netherlands