Strahman Valves Wash-Down Equipment and Industrial Valve Products

Strahman Valves is a world leader in the manufacture of high-quality wash-down equipment and industrial valve products. Since its creation in 1921 the company has earned a reputation for superior performance, innovative solutions to complex problems and long-term reliability.

Based in Pennsylvania, US, Strahman is a trusted name in the chemical, petrochemical, polymer, biotechnology, pharmaceutical, food processing, beverage, dairy, mining, and pulp and paper industries.

Sampling valves and systems

Strahman pioneered the free-flowing, non-clogging piston tank bottom valve and has established itself as a global provider of sampling valves and systems. Today Strahman offers a full range of cast and fabricated valves.

All Strahman valves can be constructed to the following specifications:

- Carbon steel

- Chrome moly steel

- Stainless steel (316L/316L, duplex)

- Noble alloys (inconel, nickel, titanium, hastelloy and alloy 20)

Strahman products feature metal-to-metal seals and seat-less sealing technologies. Metal-seated seals are designed for high-pressure and high-temperature tasks, while seat-less seals (rod seals) are used for difficult processes such as PVC or pharmaceutical applications.

The company also makes metal seals, dual seals, metal ring seals, soft seals and flow controls.

High-quality engineering means Strahman valves are compliant with the industry standards ANSI class 150-2500, API Fire Safe, NACE, TÜV (European standard), JIS and PED.

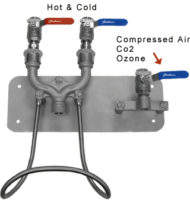

Add-on accessories such as heating/cooling jackets, limit switches, positioners (motion transmitters), solenoid valves, mounting options (NPT, flanges and welded) and quick disconnect are available for all valves.

Valve line blinds

Total equipment isolation valves are never completely reliable. For this reason most safety regulations demand positive shut-off devices such as line blinds. Strahman offers the most complete and diverse range of line blinds in the world.

While most types of line blind require adjacent piping to be moved before they are closed, Strahman has several designs that avoid this disadvantage.

Strahman line blinds’ features include:

- Total equipment isolation from pipeline leakage

- Positive positioning locking systems

- Multiple types of seal

- Drain connections on one or both sides of the line blind

- No movement of adjacent piping when thrown

- A one-man operation without climbing over the piping

- Sizes from 1¼in to 48in

- End connections as dictated by the piping system

- Virtually all metallurgies

- Pressure classes from 150ANSI to 2,500ANSI

- Compliance with ANSI, ASME, TUV, NACE, API, USN, Lloyd’s Cryogenic and Fire Safe

Swing, compact non-spill and econ valve blinds

Strahman also makes swing and compact blinds for large and small spaces respectively; non-spill blinds, which can prevent spillage when the blind is thrown; and econo blinds.

Cast and fabricated process valves

Strahman pioneered the free-flowing, non-clogging piston tank bottom valve and established itself as a worldwide leader of sampling valves and sampling systems. Today, Strahman offers a full range of both cast and fabricated valves.

Process valve range

Strahman’s process valves include:

- Ball valves

- Gate valves

- In-line valves

- Metal seated sampling valves

- Drain valves

- Sampling valves

- Diverter valves

- Spray rinse valves

- Butterfly valves

- Sanitary valves

Strahman’s process valves are constructed of carbon steel, chrome moly steel, stainless steel (316/316l or duplex) or noble alloys (inconel, nickel, titanium, hastelloy or alloy 20).

Strahman technology features metal-to-metal seals as well as seatless sealing technologies. Metal seated seals are used on high pressures and high temperature applications; our seat-less design (Rod Seal) is used for difficult process applications like PVC or pharmaceuticals.

Process valve sealing systems and accessories

Sealing systems for Strahman’s process valves include metal seal, dual seal, metal-ring seal, soft seal and flow control.

Add on accessories such as heating/cooling jackets, limit switches, positioners (motion transmitters), solenoid valves, mounting options (NPT, flanges and welded) and quick disconnect are available for all Strahman valves.

Quality engineering makes Strahman valves compliant with many industry standards, including ANSI class 150-2500, API fire safe, NACE, TÜV (the European standard), JIS and PED.

Products and Services

Video

White Papers

Related Projects

Press Release

Regional Offices

2801 Baglyos Circle

Lehigh Valley Industrial Park

PA 18020

Bethlehem

Other

United States of America

Other

United Kingdom