Pervatech Ceramic Membrane Technology for Pervaporation, Vapour Permeation and Gas Separation

Pervatech BV produces cutting-edge membranes, membrane modules and separation systems for pervaporation and vapour permeation applications.

The company uses its know-how to design membrane-based solutions for the separation of organic substances. The products and services Pervatech offers enable its customers to innovate their production processes, leading to lower energy consumption, higher efficiency, recycling of valuable resources, lower waste streams and higher product quality.

Compared with more traditional separation methodologies such as distillation and molsieves, substantial energy savings of 25% to 75% can be realised.

Permatech advises customers in the optimisation of their processes by combining knowledge of membrane processes with other existing industrial technologies.

Tubular ceramic pervaporation membranes, modules and industrial systems

The company’s core activities are the production, marketing and sales of tubular ceramic pervaporation membranes, modules and industrial systems. Pervatech has a large production capacity.

The product offering includes:

- Tubular ceramic pervaporation membranes

- Hybrid pervaporation membrane up to 150°C

- PDMS-based organophilic pervaporation membranes; spiral wound elements

- Test modules for lab scale and pilot scale

- Larger membrane modules for industrial plants

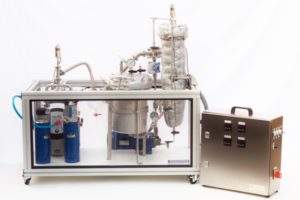

- Equipment for lab scale and pilot scale testing

- Industrial plants in co-makership with OEMs

Pervaporation technology for dehydration processes

In addition to ceramic pervaporation membranes, Pervatech serves the organophilic pervaporation market with special polymeric membranes. This is mainly focused on selective recovery of aromas and fragrances.

These are also very useful for recovery of aggressive solvents at point of release in the plant, such as lower alcohols, ethyl acetate, isoamyl alcohol, isoamyl acetate, hexanol, 2-hexenal, benzine, xylene, chlorinated hydrocarbons.

Special polymeric membranes

Pervaporation is increasingly used in the chemical, petrochemical, pharmaceutical and food industries.

Pervatech pervaporation technology is particularly useful in dehydration processes such as solvent drying, breaking of azeotropic mixtures, and enhancing chemical condensation reactions in aggressive environments.

It can be a useful add-on process for situations where other separation methods reach the end of their operational limits, for example, lack of chemical-resistance, swelling of the polymeric membrane, or temperature.

Ceramic membrane technology R&D

Pervatech’s scientific co-operation with leading universities and institutions, both nationally and abroad, secures today’s and tomorrow’s ceramic membranes with superior characteristics.

Plant realisation is in co-makership with well-established official equipment manufacturers, with full licences for PED directives, ex-directives, and availability of plant services.

The commercialisation of our pervaporation and vapour permeation technology is dealt with by the company in the Netherlands, either directly to the end-user or through process equipment manufacturers.

Pervatech is looking for processes where it is possible to reduce investments (up to 75%), a remarkable reduction of the energy costs, a significant reduction in downstream processing, and a higher-quality end-product.

Ceramic discs

Pervatech produces ceramic discs based on filtration methods, resulting in defined pores with sharp pore size distribution, especially towards the higher tail of the Gauss-distribution curve.

The hydrophilic (water wet) ceramic discs can be coated with finer pore coatings on top with different membrane materials. Also the discs can be made to be hydrophobic (oil wet).

The discs can be used in membrane development, rocksample analysis and for instrumentation purposes.

Products and Services

Video

White Papers

Lab-Scale Test Systems

Pervatech is considered a leading supplier of cutting edge membranes, membrane modules and separation systems for pervaporation and vapour permeation applications.

Lab-Scale Test Systems

Pervatech is considered a leading supplier of cutting edge membranes, membrane modules and separation systems for pervaporation and vapour permeation applications.

Hybrid Pervaporation Membrane up to 1500°C

The hybrid pervaporation membrane is particularly robust against hydrothermal attack, the presence of acids and the presence of aggressive organic solvents.

Related Projects

Press Release

Pervatech cordially invite you to attend the 11th International Workshop on Crystallization, Filtration, Granulation and Drying (WFCFD), which is set to take place at the KV Auditorium in Mumbai on 9-11 March.

Read morePervatech is to give a presentation at the European Conference Industrial Technologies 2016 on 22-24 June in the RAI Amsterdam, Netherlands.

Read morePervatech, the cutting-edge membrane producer for pervaporation and vapour permeation, and Philips Ceramics, Philips' global competence center for technical ceramics, announce their partnership by combining the superior ceramic substrates and knowledge from Philips Ceramics with the Pervatech membrane coating technology.

Read moreLeading supplier of ceramic membranes, membrane modules and separation systems for pervaporation and vapour permeation applications Pervatech has released a free white paper on Hydrocarbons Technology.

Read morePervatech, a cutting-edge producer of membranes, membrane modules and separation systems for pervaporation and vapour permeation applications, has acquired Cobra Technologies in the Netherlands.

Read moreThe HybSi® membrane has been nominated for the Accenture Innovation Award and selected as one of the 25 best candidates for the jury award in the field of energy and chemicals.

Read morePervatech, producers of cutting-edge membranes, membrane modules and separation systems for pervaporation and vapour permeation applications, has secured the necessary financial support required for the company's expansion.

Read moreFor the ISPT Techno project, titled "Recovery of aggressive solvents, which are difficult to separate", Pervatech modified and tested ceramic membranes. These tests showed that it is possible to tailor a membrane towards an optimum for the separation of volatile aromatic organic components from an ethanol / water stream.

Read moreWe are happy to announce that Pervatech will be present at the 9th European Congress of Chemical Engineering.

Read morePERVATECH BV, established in 1999 is a leading company in membrane technology. Based on the belief that we have an obligation towards future generations to preserve Earth's resources, we develop products and services that enable customers to innovate their products and production processes towards lower energy consumption, less waste and higher quality.

Read morePervatech has been announced as a gold level sponsor of the International Scientific Conference on Pervaporation, Vapour Permeation and Membrane Distillation in Toruñ, Poland 12-15 May 2013.

Read moreWe are pleased to inform you that Pervatech will be attending the Euromembrane 2012 conference to be held at the Queen Elizabeth II Conference Centre, London on 23 to 27 September 2012.

Read moreHybSi® membrane systems will be presented at events around the world later on this year.

Read morePervaporation using ceramic HybSi® membranes can deliver 30% to 50% energy savings relative to conventional distillation.

Read morePervaporation is the selective evaporation of one of the components of a liquid mixture using a membrane.

Read moreCurrently available commercial pervaporation membranes are limited by their stability, in

especially strong organic solvents and under acidic conditions. In recent publications the

unprecedented stability of HybSi® membrane technology is reported.

Pervatech, an innovative Dutch specialist in pervaporation membrane technology, is the first industrial partner to obtain a licence for the commercialisation of the HybSi® membrane technology.

Read moreRegional Offices

Heliumstraat 11

7463 PL RIJSSEN

Netherlands