HOT Engineering Geophysical Exploration and Field Development Services and Training

HOT Engineering is a reservoir consultancy company headquartered in Austria. With more than 20 years of consulting experience, we are one of the leading providers of advanced and integrated geological, geophysical, petrophysical, reservoir and production engineering technology and are well positioned to offer state-of-the-art training.

Exploration and field development services

We provide the following wide range of exploration and field development services:

- Petrophysical and sedimentological analysis and interpretation

- Sequence stratigraphy

- Open-hole log interpretation and formation evaluation

- Cased-hole log interpretation and reservoir monitoring

- Geophysical interpretation

- Seismic inversion

- AVO / attribute analysis and quantitative interpretation

- Reservoir characterization and modelling

- Well-test interpretation

- Fluid characterization

- Reservoir engineering

- Reservoir simulation (black oil and compositional)

- Improved and enhanced oil recovery

- Field development planning

- Reserves’ management

- Well planning

- Production optimization

We can integrate these services seamlessly with geophysical processing and data management services.

Geophysical interpretation, reservoir characterization and modelling, flow simulation and field development

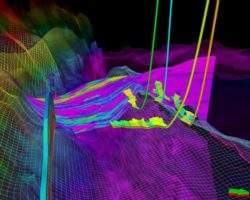

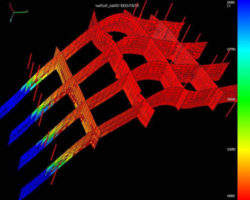

We offer fully integrated services starting from geophysical interpretation and reservoir characterisation, all the way through to reservoir modelling, flow simulation and field development. Our special area of expertise is the development of seismically consistent, high-resolution 3D static and dynamic reservoir models.

We have carried out studies around the world. We have worked on oil and gas reservoirs, on underground gas storage, in clastic and carbonate environments, on heavily faulted and fractured reservoirs, on new discoveries and mature giant fields, and have elaborated field development plans covering a variety of development strategies. Examples of our key achievements are as follows:

- Re-developed the field development scheme for a mature field; actual production tripled in accordance with our forecast made six years ago

- Changed production strategy for a giant field; customer was able to defer and significantly down-size water injection and thus achieve major savings

- Defined new exploration prospects; found several structures nearby a producing field; drilling confirmed the presence of hydrocarbons

- Re-developed a large carbonate field; kept customer from investing in CO2 injection, which would have resulted in premature CO2 breakthrough and no increase in oil recovery

- Optimized water flooding scheme in a giant carbonate reservoir, resulting in a significant increase of oil production rate, while water production was reduced

Seismically consistent reservoir modelling

We incorporate seismic and other data directly into the reservoir modelling process, which results in a range of possible reservoir models being considered.

Geo-pressure predictions

Understanding geo-pressures is essential for safe and efficient drilling as having a too low mud weight can result in dangerous kicks and blowouts, or alternatively a mud weight being too high can result in formation damage, lost circulation and stuck drill pipe. This is crucial for optimising the casing scheme.

We offer pressure predictions from good-quality seismic data, based on the accurate estimation of interval velocities.

Fracture analysis

Fracture analysis from pre-stack seismic data can provide a better understanding of fracture density and orientation. The integration of fracture analysis with seismic and detailed reservoir modelling provides a powerful approach for handling fractured reservoirs.

Hydrocarbon studies, engineering assessments and modelling

Studying the impact of water injection in a mature producing field implies the integration of sedimentological, petrophysical, geophysical and geological studies, plus engineering assessment and simulation modelling, combined with rigorous database management to capture the large amounts of data from the different domains. As a result of one of our studies, our customer was able to defer and significantly down-size water injection, and thus save significant amounts of capital and operational expenditure.

CO2 injection studies

Studying the potential impact of CO2 injection, we integrated seismic modelling, inversion, petrographical, petrophysical analysis, facies analysis, porosity and permeability modelling, fracture network modelling, fluid characterization, black oil and compositional reservoir simulation and performed economic modelling.

At the end of the study, our customer had to conclude that the injected CO2 would move mainly along the fracture network and that CO2 breakthrough would occur within a matter of days after start of injection. Furthermore, injected CO2 would displace very little oil from within the matrix and continuation of the current production practice would yield a higher recovery than the CO2 scenario.

Hydrocarbon recovery development scheme

For a mature carbonate field with 25 years of production history, we designed a development scheme that more than tripled production. The comparison of the actual oil production and our forecast, which was forecasted six years ago, shows an excellent match between the actual and forecasted production.

Products and Services

Video

Related Projects

Amur Gas Processing Plant, Amur Region

Glenaras Gas Project, Queensland

Ungani Oil Field

Western Surat Gas Project

Kincora Project Gas Project, Queensland

Paradip Refinery, Odisha

Sabine Pass LNG Terminal

Swinoujscie LNG Gas Terminal, Baltic Coast, Poland

Naoetsu LNG Receiving Terminal

Regional Offices

Parkstrasse 6

Leoben

A-8700

Other

Austria