Continuous Control Solutions Turbo Machinery Control Solutions

Continuous Control Solutions (CCS) provides turbo machinery control solutions, including turnkey compressor anti-surge and gas / steam turbine control systems, to the oil and gas, chemical, metallurgy and power generation industries worldwide. Our services department can provide control systems servicing for all platforms inclusive of start-up and commissioning, and ongoing maintenance and servicing.

Our systems are flexible, transparent and robust, focusing on the customer’s entire process, in addition to protecting machines, providing a true continuous control engineering solution tailored individually to each project according to the customer’s needs.

Flexible turbo machinery control systems

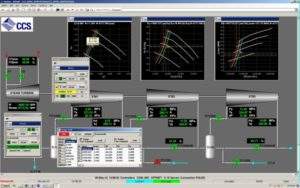

We offer customers unparalleled flexibility to choose their own IEC6113-compliant PLC to run our patented turbo machinery control applications. Unlike a typical ‘black-box’ compressor anti-surge solution or OEM-provided gas / steam turbine control system, CCS control applications can integrate seamlessly with an existing DCS.

Our patented control algorithms have already been adapted to different off-the-shelf PLC products such as Honeywell C-200/300-20, Yokogawa Stardom, Allen Bradley ControlLogix, Emerson Delta V, Siemens S7, ABB AC800, Wago I/O System 751 and Beckhoff CX, making us the most flexible control solutions provider in the market.

Custom controls for PLC, PC and DCS systems

We create and install new and retrofit programs – including lump sum turnkey (LSTK) integrated plant controls, modelling and simulation tasks – to meet your company’s unique needs. Our experienced engineers develop custom controls for your PLC, PC or DCS systems, and provide round-the-clock support to keep your systems running safely and efficiently.

CCS control applications, combined with our market-leading expertise, provide custom-tailored engineering solutions, including:

- Surge prevention control

- Speed / fuel control

- Parametric diagnostics

- Sequencer and ESD system

- Control system HMI

- Periodical and critical archive

- Station control

- Load balancing

- Station optimisation

- Efficiency comparator

- Turbo machinery control systems

We use experience, research, information technology, mathematics and statistics to design applications that give you complete control over your drivers – e.g., gas turbines, steam turbines and expanders – and driven units – e.g., compressors, pumps and generators. We use leading third-party hardware and software products, combined with our patented algorithms, to build controls to your specifications – ensuring compatibility with your current operating system. You can count on our digital controls and mechanical-hydraulic modifications to increase your system’s reliability and reduce operating costs.

Surge prevention controller for compressors

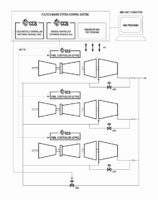

CCS’s patented surge prevention controller (SPC) protects your centrifugal or axial compressor from costly and damaging surge. The SPC allows you to define the safety line under variable conditions giving you optimum surge protection without unnecessary recycling or blow-off. CCS’s patented SPC provides two independent control loops, dP and Rc.

During normal operations, CCS systems offer a high-select mode and control based on the most efficient variable. If at any point in the process either measurement becomes unavailable, CCS provides true continuous control by automatically controlling based on the available control loop.

Station controller for compressors

CCS’s station controller (SC) can load-share or load-balance multiple compressor trains, and manage single compressor trains and cold recycle valve arrangements to protect your turbo compressors with minimal intervention.

Customers have the option to predefine target controls for units working in parallel and / or series operation modes to optimize compressor efficiency and speed, or minimise station fuel gas consumption.

CCS SC delivers bumpless transfers between manual and automatic operating modes and between main, alternative or limiting control loops.

CCS station controller advantages

The CCS station controller has a number of advantages, including:

- State-of-the-art surge prevention techniques utilize patented compressor pressure ratio control methods, even when flow is unavailable

- Load balancing of multiple turbo machinery units/trains on actual and real-time efficiency of gas turbine, compressors and/or generators

- Specifically designed for units differing in size and rapidly changing process conditions

- Patented efficiency comparator for analysis of unit and/or plant operation

- Gas / steam turbine fuel / speed controller

- CCS control applications for gas turbine fuel control and steam turbine speed control (GTFC or STSC) are effective alternatives to costly OEM turbine control retrofit packages

Turnkey turbo machinery control solutions

CCS excels in turbo machinery control installation, retrofit, engineering and support. Our services cover a broad range, from project front end engineering and design (FEED) study, to turnkey installation management, to detailed systems engineering.

Our project scope commonly includes conceptual and systems design, project engineering and management, programming, commissioning, training and much more.

About CCS

CCS is headquartered in Des Moines, IA, US, and has offices in Amsterdam, Netherlands; Moscow and St. Petersburg, Russia; and Kharkov, Ukraine. In addition, we have distribution partners in Central Asia, China and Azerbaijan as well as representative partners throughout Latin America.

CCS is also an official Turbo Machinery Controls Partner for Honeywell Process Solutions, an official Turbo Machinery Controls Partner for Yokogawa International and a Recognised System Integrator with Rockwell Automation.

Products and Services

Video

White Papers

CCS Implementation of Surge Prevention Control System on Yokogawa Stardom PLC

Due to the increasing demand for compressor and turbine control systems to be implemented in a common hardware with plant DCS, CCS has partnered with Yokogawa to offer advanced, proven and tested turbo machinery controls solutions on the Yokogawa Stardom PLC.

Implementation of Surge Prevention Control System on Yokogawa Stardom

The air separation unit located at the Lukoil Karpatneftekhim plant in Kalush, Ukraine was designed and built in 1996. According to the CCS initial site survey report, the air compressor began experiencing problems in 2010.

The Next Generation of Turbo Machinery Control

Continuous Control Solutions (CCS) provides the next generation of control technology and solutions inclusive of design, implementation and commissioning of reliable, high-quality control systems for industrial turbo machinery control applications.

Related Projects

Northeast Supply Enhancement (NESE) Project

Visakh Refinery Modernisation Project, Visakhapatnam

Press Release

Continuous Control Solutions (CCS) has released a free white paper with information on the compressor control system installed at the Lukoil Karpatneftekhim plant in Kalush, Ukraine.

Read morePlease come and visit Continuous Control Solutions (CCS) in the Demo Room at the 2013 Honeywell Users Group Americas Symposium, which is being held at the JW Marriott in Phoenix, Arizona, 16-21 June.

Read moreContinuous Control Solutions (CCS) is proud to announce that it has been designated as an official turbo machinery controls supplier to MAN Diesel & Turbo Oil & Gas.

Read moreAs a testament to our advanced control algorithms and the individuality of CCS control systems, CCS is the proud holder of patents for dual-loop (dP- and Rc-based) surge prevention control (for compressors) and dynamic optimisation of machines.

Read moreRegional Offices

11275 Aurora Ave

Des Moines

50322

Indiana

United States of America