ROSEN Group Pipeline and Tank Inspection

The ROSEN Group provides a full range of inspection services for complex and sensitive engineering structures such as oil and gas pipeline systems and above-ground storage facilities.

Operating in more than 100 countries worldwide ROSEN’s products and services to the oil and gas industry cover pipe diameters from 3in up to 64in for any length or configuration (e.g. 1.5D bends, dual diameter pipelines, multi-diameter pipelines).

Pipeline and tank inspection

- Pipeline cleaning tools and accessories

- In-line cleaning

- High-resolution geometry inspection

- XYZ mapping

- High-resolution metal loss inspection

- Customized in-line inspection

- EMAT crack detection and coating disbondment

- Ultrasonic crack detection

- Ultrasonic corrosion detection

- Multi-diameter pipeline inspection

- Shallow internal corrosion inspection

- Optical inspection

- Leak detection

- Robotic inspection

- Plant and facility inspection

- Hydrostatic testing and commissioning

- Data services

- Asset integrity management support

- Asset integrity management software

- Pipeline-, plant- and facility rehabilitations

EMAT crack detection and coating disbondment tool (ROCD²)

Electro Magnetic Acoustic Transducer (EMAT) technology is based on electro-mechanical conversion produced when an eddy current is applied within a static magnetic field. The resulting Lorentz forces and magnetostriction result in an interaction between the EMAT and the metal surface generating an acoustic wave within the material, eliminating the need for liquid couplant.

The acoustic wave that propagates within the pipe wall is dependent on the dimensions and properties of the pipe material. Therefore, the presence of SSC and other crack features will disturb the guided-wave in such a way as to produce a reflection resulting in an echo. This echo can be detected and measured.

ROSEN’s high-resolution tool RoCD2 provides the above mentioned approach. The tools service is based on a unique and highly effective implementation of an EMAT to induce guided acoustic waves within the pipe wall regardless of the pipeline contents.

The result is a high quality and reliable signal precisely controlled in wave length and frequency limiting detection to cracks and crack colonies and minimizing detection of other intrinsic anomalies of the pipeline. In addition, the technique is used to collect coating disbondment information.

Pipeline dent detection

Based on 25 years of experience in ILI technology, ROSEN has developed a unique tool for characterizing and sizing dents. RoGeo•Xt incorporates high-resolution technology combining a touch-less electronic measuring system with the conventional calliper arm tools. This dynamic compensation technology provides highly accurate results both under dynamic and static conditions.

The tool is based on an innovative concept: it combines a traditional mechanical caliper arm with an electronic distance measurement system, thereby optimizing measurement accuracy and providing 100% circumferential coverage. Traditional mechanical caliper tool designs generate position signals on the basis of the movements of a mechanical arm.

Since increased tool speeds mean that the mechanical arm can lose contact with the inner pipe wall while abrupt changes in the internal surface may lead to inaccurate measurements, this puts severe limitations on inspection speed. RoGeo•Xt overcomes these difficulties thanks to its ‘mechatronic’ design.

Combined MFL / ultrasonic corrosion detection

ROSEN’s inspection tool RoCorr•MFL/UT employs twin inspection technologies to achieve enhanced performance in defect detection and sizing. RoCorr•MFL/UT tools combine the latest generation of MFL technology and state-of-the-art ultrasound technology (UT). This advanced range of high resolution tools is based on a unique modular concept which allows the tools to be used in a variety of specialized configurations.

Advanced software solution

The primary objective of an integrity program is to maintain the pipeline in a fitness-for-purpose condition and in a safe and cost-effective manner. Standards and codes of practice are available which provide clear guidance for the practical implementation of pipeline integrity management in a logical and consistent manner.

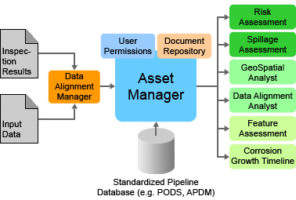

ROSEN has developed a suite of software tools which meets the technical and functional demands. The ROSEN Asset Integrity Management Software (ROAIMS) is made up of a number of functional modules that can be combined to configure different integrity management applications.

Following an initial audit of an operator’s specific requirement the system can be customized as needed, ranging from a simple data storage / repository to a comprehensive integrated integrity management software solution.

Products and Services

Video

White Papers

Related Projects

Karaikal LNG Import Terminal, Puducherry

NGTL System Expansion Project, Alberta

Sandpiper Pipeline Project, Minnesota

Tema Liquefied Natural Gas (LNG) Terminal

Horn of Africa Pipeline

Press Release

ROSEN has announced that it will present its new approach for pipe properties and a maximum allowable operating pressure (MAOP) validation at this year's Pipeline Pigging & Integrity Management Conference (PPIM).

Read moreThe ROSEN Group has introduced the globally first 4in in-line inspection tool utilising high resolution ultrasound technology for wall thickness measurement and crack inspection services.

Read moreROSEN is a leading privately owned company serving the oil and gas industry with inspection, integrity, and rehabilitation products and services. For 30 years, ROSEN has provided the industry with advanced inspection and integrity solutions to ensure safe and economical operation of a wide range

Read moreThe ROSEN Group is pleased to announce its recent award of four major baseline pipeline inspections worth around $9m for the Chevron-operated Gorgon Project. Managed out of ROSEN's Canning Vale operating facility, the multi-million dollar project is planned to start immediately with des

Read moreWith the introduction of the CE device Directive ATEX 94/4/EC (ATEX 95) and the Occupational Health and Safety Directive ATEX 1999/92/EC (ATEX 137), a uniform legal basis was established for explosion protection within the European Union. The CE directives were completely harmonised an

Read moreMr. Raymond Lewis, director of business development for ROSEN USA, has celebrated his 60th year in the pipeline industry in 2011. To commemorate such a momentous occasion, Mr. Lewis' peers gathered together during the recent Pipeline Pigging and Integrity Management Conference for a surp

Read moreROSEN is pleased to announce the successful completion of the second year of the five-year contract with National Grid, owner and operator of Great Britain’s high-pressure natural gas pipeline network and four lower-pressure distribution networks. The pipeline inspection services contrac

Read moreThere is a substantial market for pipeline security technology in both oil-producing and oil-consuming regions in the world. Depending on the location and age of the pipeline system, however, the required features of monitoring systems for asset integrity and pipeline defects differ and fall into

Read morePipeline integrity management is a complex process involving people, assets, procedures, data gathering, analysis and commercial consideration in terms of production, operations and maintenance costs. The primary objective of an integrity program is to maintain the pipeline in a fitnes

Read moreSaudi Aramco and the ROSEN Group announced the signing of a Memorandum of Understanding (MOU) to conduct joint research and development in Non-Destructive Testing (NDT) technologies for the oil and gas industry. Mr Isam A. Al-Bayat, VP, Saudi Aramco Engineering Services, and Mr. Hermann

Read moreA growing number of pipeline operators are now turning their attention to the relatively new phenomenon of black powder in gas lines, because of the substantial effects it has on their pipeline systems. Consisting mainly of iron and sulfur as well as iron oxide in different chemical combinations,

Read moreRegional strain caused by earthquakes, landslides and other third-party influences can have a severe impact on pipeline integrity. Since strain is the result of an interplay between a number of very different factors, local and especially regional strain can only be reliably detected by means of

Read moreDespite being an important technology used to detect many different types of defects in pipelines, Magnetic Flux Leakage (MFL) is not the ideal method for identifying certain geometries, notably large uniformly corroded areas and two-dimensional mid-wall discontinuities such as laminations.

Read moreROSEN has available a full range of in-line inspection tools, designed to withstand the most adverse conditions yet return accurate data on pipeline integrity and other anomalies. From internal corrosion to dent and wrinkle inspection, cracks and pipe geometry, a ROSEN tool is available for any t

Read moreRegional Offices

Rua Aguiar Moreira, 346 – Bonsucesso

CEP 21041-070 Rio de Janeiro-RJ

Other

Brazil

Am Seitenkanal 8

49811 Lingen

Other

Germany

Zutphenstraat 15

7575 EJ Oldenzaal

Other

Netherlands

Obere Spichermatt 14

CH-6370 Stans

Switzerland

PO Box 61408

Dubai

Jebel Ali Free Zone

Other

United Arab Emirates

5020 12a Street SE

Calgary

Alberta

T2G 5K9

Other

Canada

Calle 2 No. 100, Col. Lecheros

Boca del Rio

Veracruz, C.P. 94295

Other

Mexico

14120 Interdrive East

Houston, Texas 77032

Other

United States of America

1 Jalan Jurubina U1/18

HICOM Glenmarie Industrial Park

Selangor

40150 Shah Alam

Other

Malaysia