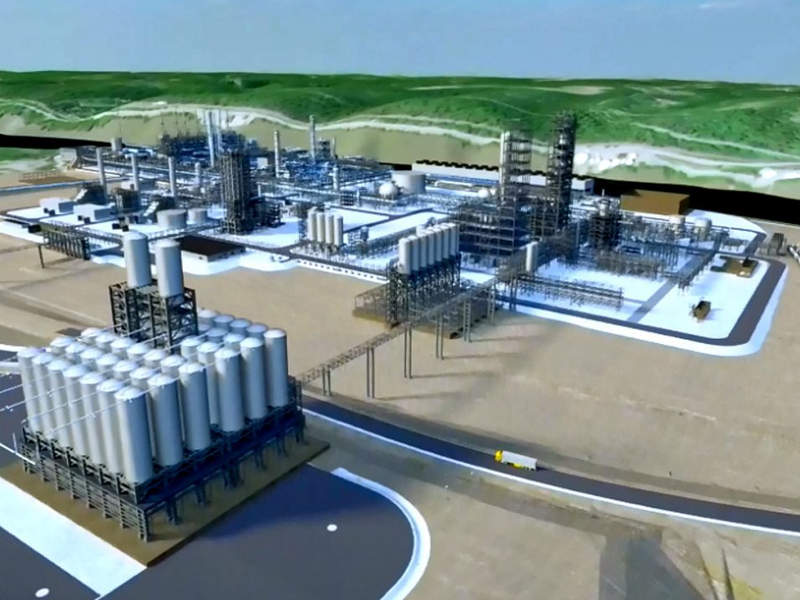

Chemex Modular Refineries and Modular Gas Plants

Chemex is an American company that specializes in the manufacture of modular petroleum refineries and modular gas plants. Chemex has successfully designed, fabricated, delivered, and installed process units across the globe since 1978. Chemex also carries a large inventory of used and refurbished petroleum and gas processing equipment.

Modular petroleum process units

Chemex manufactures the following modular petroleum process units:

- Atmospheric and vacuum distillation units

- Naphtha and distillate hydrotreater units

- Hydrocracker units

- Catalytic reformer and isomerization units

- Splitters, stabilizers, desalters and flares

Modular construction of refineries and gas plants

Modular construction shortens on-site installation time and customer operating revenue is achieved sooner.

With conventional foundation-mounted refinery equipment, each piece of equipment is placed on its individual foundation at the refinery site and welders pipe the equipment together. This ‘stickbuilt’ method requires significantly longer construction time than Chemex’s modular fabrication.

In modular construction, rather than assembling all of the components of a refinery or gas plant at the refinery site, the facility’s structure is reduced to smaller elements that can be assembled more efficiently and rapidly at Chemex’s fabrication plant. Modular construction typically costs between 65% and 80% of traditional ‘stickbuilt’ construction.

High-quality modular petroleum refineries and gas plants

By performing most or all of the fabrication and assembly at Chemex’s manufacturing facility, the modules as well as the workers that put them together are not subjected to environmental dynamics like heat, wind, rain or freezing temperatures. Controlled working conditions allow Chemex to produce a higher-quality product – the metal is less prone to expansion and contraction from temperature fluctuations, and welding equipment runs on steady voltage from the local California power grid.

Modularization also minimizes inclement weather delays and reduces costs since high-cost field work hours are transferred to lower-cost shop hours. Building with modules reduces the need to maintain a skilled construction crew on or near the refinery site.

Fabricated modular process units

Fabricating modular process units away from the refinery’s final site reduces the impact of construction on the customer’s site, a significant advantage when the installation site already is an operating plant. Modular construction also minimizes lay-down space, an important consideration when the field site is small or congested. Elevated work is minimized, and foundation requirements are often simplified.

Modular refineries and plants with pre-fitted components

Pre-fitting components onto a module permits correction of any fitting errors prior to shipment to a customer’s plant, with less re-work needing to be performed on-site. Procurement also is simplified, especially when the installation site is located where raw materials and equipment are expensive or difficult to obtain.

Chemex maintains great relationships with its supply chain and in turn is able to procure manufacturing components with ease, saving the customer time and money. Removing the need for highly skilled labor on site offers an added advantage in areas where skilled labor is either costly or unavailable.

Skid-mounted modular equipment for concrete slab foundations

Chemex designs its skid-mounted modular equipment for placement on concrete slab foundations. A module leaves Chemex’s fabrication plant nearly complete, with most of its support structure, pipe, instrument mountings, electrical wiring, grating, fireproofing, insulation and other components built in and ready for operation, once connection is made to the refinery’s systems.

All Chemex modular equipment is transported by truck, rail or ship to each refinery site; the modules are then assembled with the advice of Chemex’s experienced installation team. When the equipment arrives at the facility site, it is unloaded and set on the concrete slab foundations. Final skid placement and elevations are checked against the drawings and skids are shimmed and adjusted accordingly.

Chemex’s experienced start-up team oversees every installation, commissioning, start-up and test-run, to ensure 100% success.

Financing for modular refineries and plants

Chemex can assist in financing your project through the US Export Import (EX-IM) bank. Chemex is also able to arrange global medium-term financing through the US EX-IM bank for many of its clients.

Contact us today for all your modular refining and gas processing needs.

Products and Services

Video

White Papers

Related Projects

Amur Gas Processing Plant, Amur Region

SemCAMS Wapiti Sour Gas Plant, Alberta

Jebel Ali Refinery Expansion Project

Shell Pennsylvania Petrochemicals Complex

BOSTCO Project, Houston

Diamond Pipeline

Press Release

Chemex has long been a leader in the supply of quality used oil and gas processing equipment. Chemex has a comprehensive used equipment inventory spanning over 13 acres in Bakersfield, California, US. Chemex is proud to announce that its entire inventory of used equipment is now

Read moreRegional Offices

2221 Mohawk Avenue

Bakersfield

93308

California

Other

United States of America