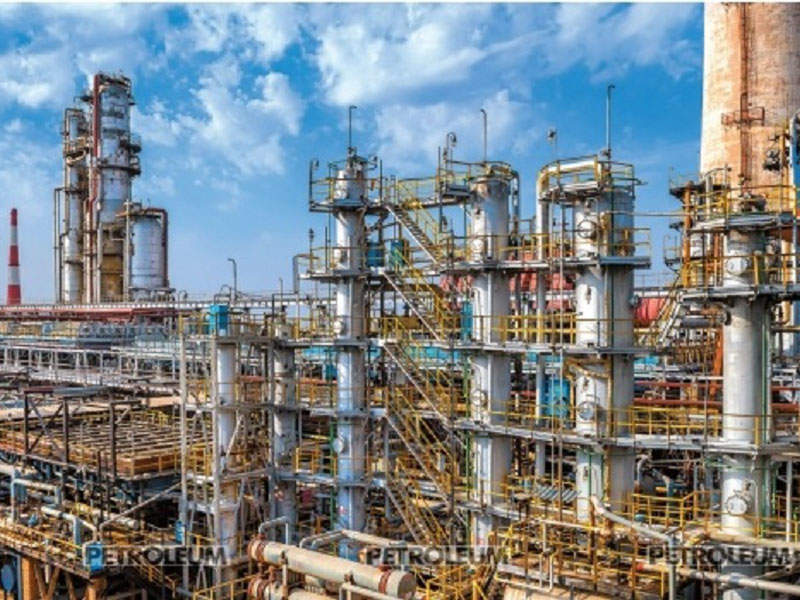

ATB Riva Calzoni Plant Design and Engineering Services and Process Equipment Manufacturing

ATB Riva Calzoni operates in the energy industry and is divided into hydrocarbons and renewable power sectors.

ATB Riva Calzoni oil and gas division offers a wide range of services for the hydrocarbons sector. The company supplies process packages for engineering, services for engineering, procurement and construction (EPC), pressure vessels, evolved packet systems (EPS) and operation and maintenance (O&M) services.

Hydrocarbons engineering and design services

Through its controlled company DG Impianti, ATB Riva Calzoni’s engineering and design business unit delivers a comprehensive range of services, from commissioning and start-up assistance to conceptual and feasibility studies.

As a front-end engineering and design (FEED) provider, ATB employs a multidisciplinary approach, using its value engineering capabilities and project experience.

The company uses state-of-the-art technologies and the latest methodologies to create solutions for clients in the hydrocarbons industry.

ATB Riva Calzoni provides optimised project development solutions through evaluation and screening of relevant products and technologies.

ATB employs a typical front-end gate process that works with the client to analyse different solutions for various field development scenarios.

Engineering, procurement and construction packages for oil and gas projects

ATB Riva Calzoni’s engineering, procurement and construction (EPC) division offers clients competencies such as procurement, project execution, fabrication, installation and commissioning services.

Main contracting of mission-critical solutions for the upstream / downstream oil and gas and power plants is also available.

The company’s key competencies in EPC packages for hydrocarbon projects include:

- Turnkey deliveries of oil and gas production, and processing installations

- Project engineering, procurement services, and fabrication and start-up services

- In-house expertise of fabrication and completion services

The production phase of oil and gas facilities is strictly controlled to ensure that each aspect meets customer specifications and requirement codes.

Calculation methods and construction techniques are carried out in compliance with a wide range of national standards.

This includes the American National Standards Institute (ANSI), the American Society of Mechanical Engineers (ASME), the Tubular Exchanger Manufacturers Association (TEMA), the American Petroleum Institute (API) and Germany’s Technical Inspection Association (TUV).

ATB Riva Calzoni’s engineering and design services include:

- Expediting

- HSE studies

- Multi-disciplinary detailed design

- Environmental impact assessment and environmental studies

- Testing and start-up

- Existing hydrocarbon plant surveys and optimisation engineering

- Installation engineering

- Feasibility studies and economics

- Asset integrity management (AIM) Construction assistance

- Pre-commissioning and commissioning follow-up

- Operability and maintenance assessment and engineering

ATB Riva Calzoni supplies process packages, including:

- Vapour recovery unit (VRU)

- Sweetening units (absorption and membrane)

- Refrigeration units

- Polishing units (MRU mercury removal from natural gas, propylene purification unit, ethylene purification unit, LPG purification unit)

- Nitrogen generator

- Hydrogen recovery or purification (PSA and membrane)

- Oil desalting and dehydration units

- Hydrocarbon recovery or dew point control

- Gas dehydration units (absorption, DEG and TEG)

- Sweetening units (absorption and membrane) Fuel gas conditioning

- Condensate stabilisation

Vanadium modified alloy steel components

ATB is a leading manufacturer of chromium and molybdenum materials, including the latest generation of vanadium-modified alloys.

The company also specialises in welding stainless-steel and duplex urea-grade, corrosion-resistant material.

ATB manufactures a wide range of components such as:

- Reactors and separators for hydroprocessing applications

- Urea reactors and auxiliary vessels

- Separators with internals for upstream applications

- Ammonia converters and auxiliary vessels

- Reactors for various downstream and petrochemical applications

- Pressure vessels (high, medium or low-pressure) and drums

- HP adsorbers columns and towers (high, medium or low-pressure)

- Shell and tubes heat exchangers (medium and low-pressure)

- Steam drums

- Storage tanks and bullets

- Pig launchers / receivers

- Subsea equipment

- Nuclear steam supply system (NSSS) components for nuclear power plants

- Nuclear casks

Pressure equipment for hydrocarbon processing applications

ATB manufactures pressure vessels for upstream, midstream and downstream applications.

Due to continuous improvement at refineries and petrochemical plants, the thickness, diameter and weight of reactor vessels have increased significantly.

With cutting-edge equipment and skilled workers, ATB specialises in producing reactors and heavy-wall pressure vessels with differing dimensions:

- Maximum thickness: HCK reactor with thickness of 358mm

- Maximum weight: HDT reactor with weight of 1,400t

- Maximum length: C2C3 splitter column with length of 100m

The company has manufacturing facilities in Italy and Malaysia, through its controlled company MMHE ATB JV. Both have direct access to the sea in Pasir Gudang, Malaysia and Porto Marghera, Italy.

About ATB Riva Calzoni

ATB Riva Calzoni was established in 2003 by combining Acciaieria e Tubificio di Brescia (ATB) and Riva Calzoni Impianti (Riva Calzoni).

The company has increased to meet the rising demand for components within the oil and petrochemical industries, as well as thermoelectric and hydroelectric power plants.

Both companies have operated for more than 100 years in the design, manufacturing and installation of mechanical equipment for a range of industrial applications.

Products and Services

Video

White Papers

Related Projects

Al-Zour LNG Import Terminal Project, Kuwait

SemCAMS Wapiti Sour Gas Plant, Alberta

Shymkent Oil Refinery Modernisation

Tangguh LNG Expansion Project, Papua Barat Province

In Salah Southern Fields Development Project

Diamond Pipeline

Chuandongbei Project, Sichuan Basin

Press Release

Regional Offices

Via Industriale, 13

Roncadelle BS

Via Industriale, 13

Italy