CEPS Pipeline Services and Pipeline Integrity Services

CEPS provides a comprehensive portfolio of pipeline services and pipeline integrity services needed during pre-commissioning, commissioning, putting in operation, decommissioning, shut-down, repair and rehabilitation as well as pipeline abandonment works.

The main services are: pigging services, mechanical and chemical pipeline cleaning and gauging, hydrostatic testing, pipeline and piping system drying, nitrogen services, revalidation, upgrading and rehabilitation of existing pipelines, pipeline defect assessment, design, delivery and installation of pipeline reinforcing sleeves, design and manufacturing of pig traps and project management.

Pigging services, mechanical and chemical pipeline cleaning and gauging

Mechanical and chemical cleaning of pipelines require different kinds of pigs, pipeline gauging, the development of specific pigging programmes for difficult pipelines, and the use of specially designed water or oil soluble cleaning agents.

Chemical cleaning of pipelines transporting hydrocarbon liquids is the most effective, safest and environmentally responsible pipeline cleaning solution that makes many pipeline maintenance, conversion, remedial repair, revalidation, decommissioning or abandonment projects feasible and dramatically reduces the required shut-down time.

CEPS provides turnkey solutions including engineering studies, work procedures, individual pig traps and manifolds, pigs, chemical reagents tailored to the composition of debris, pipeline chemical cleaning operation, project management, biological degradation and disposal of wastes.

Hydrostatic testing

CEPS operates complete sets of equipment for flooding, hydrostatic testing and dewatering of high-pressure pipelines measuring up to 56in, including high-pressure and high-capacity pumps, and unique computerised test monitoring and control systems based on the highly accurate metering equipment.

Our field engineers, with more than 20 years of experience using this state-of-the-art equipment, validate the pipeline integrity with the highest level of safety and reliability. We offer hydraulic tests according to any required specification, including stress-tests where the controlled pressurisation creates a strain in the pipeline wall in the range of the real yield stress of the steel.

Drying of pipelines and piping systems

Drying of pipelines is essential for reliable pipeline operation, as it prevents internal corrosion, formation of hydrates in gas pipelines and also freezing of water in above-ground piping and gas pressure regulators. Our efficient air drying and vacuum drying equipment removes water from pipelines quickly and efficiently. We can provide solutions optimising the time and cost of each project using both methods.

Nitrogen services

Replacing dangerous or undesirable liquids, vapours and gases in the process units or in the pipelines with nitrogen prevents dangerous work conditions in the hydrocarbon industry and pipeline transportation. Nitrogen purging and hydrocarbon displacement services help to reduce costs, protect people and nature during process units or pipeline commissioning, remedial repair, decommissioning and abandonment.

CEPS operates several membrane nitrogen units that produce nitrogen from the air directly on the site. This method not only saves nitrogen transportation costs to remote places but can also be used on sites inaccessible to heavy cryogenic nitrogen tanks.

Our engineers can create the most effective procedures for any application.

Revalidation, upgrading and rehabilitation of existing pipelines

CEPS expertise enables us to provide a complete package of services enabling our customers to significantly extend the period of safe and reliable operation of their high-pressure steel pipelines, to improve and verify the actual level of safety and reliability, to re-confirm the integrity and design factor after a long period of pipeline operation or even to increase the maximum allowed operation pressure in order to increase the transport capacity.

Defect assessment, design, delivery and installation of pipeline reinforcing sleeves

CEPS reinforcing steel sleeves filled with epoxy composition have been extensively tested and approved as a permanent repair method of defects on high-pressure pipelines transporting gas, oil and other chemicals.

We offer welded and non-welded sleeve design and also provide steel sleeves to be welded to the pipeline by circumferential welds and tailored design of repair sleeves for leaking defects. Used epoxy composite resin features high adhesivity to steel and high hardness for perfect transmission of strain from the pipe wall to the sleeve. We provide and install carbon fibre-epoxy pipeline reinforcing wraps suitable for the repair of pipeline elbows and branch connections.

Please use the form below to send us your enquiry.

Products and Services

Hydrostatic Testing and Pipeline Drying

CEPS provides turnkey commissioning services including engineering studies and/or specification development, pipeline cleaning and gauging, chemical treatment of test water, and much more.

Nitrogen Services

CEPS nitrogen services use membrane units producing nitrogen directly on the site from the air.

Pigging Services – Mechanical and Chemical Pipeline Cleaning and Gauging

We provide mechanical pipeline cleaning and gauging, chemical cleaning with oil and water soluble reagents, application of corrosion inhibitors on internal pipeline surface, and more.

Defect Assessment, Design, Delivery and Installation of Pipeline Reinforcing Sleeves

CEPS provides an in-ditch assessment of pipeline defects and analysis of defect severity, design, delivery and installation of steel pipeline reinforcing sleeves, grouted pipeline reinforcing sleeves and carbon fibre-epoxy pipeline repair wraps.

Revalidation, Upgrade and Rehabilitation of Existing Pipelines

Hydrostatic retesting of existing pipelines allows revalidation and upgrading and verifying the pipeline strength needed for its future safe and reliable operation at the specified MAOP.

Video

White Papers

Related Projects

Karaikal LNG Import Terminal, Puducherry

Swedegas LNG Facility, Port of Gothenburg

Dirok Gas Field, Assam

Ridley Island Propane Export Terminal Project, British Columbia

Baltic Pipe Project

Bezzecca Gas Field, Po Valley

Tornio Manga LNG Terminal

NGTL System Expansion Project, Alberta

Alton Natural Gas Storage Project, Nova Scotia

Gladstone Liquefied Natural Gas Project

Diamond Pipeline

Surmont Phase 2 Oil Sands Project, Alberta

Chuandongbei Project, Sichuan Basin

Coastal GasLink Pipeline Project, British Columbia

South Jersey Gas (SJG) Natural Gas Pipeline, New Jersey

Western Corridor Gas Infrastructure Development Project

Prince Rupert LNG Project, British Columbia

Alaska LNG Project

Southern Corridor Gas Pipeline

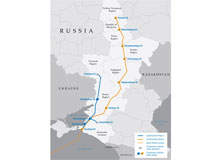

Baltic Pipeline System–2

Press Release

Regional Offices

Belnicka 628

Jesenice

252 42

Czech Republic